Canberra International Sports and Aquatic Centre.

Canberra International Sports and Aquatic Centre.

Australian Manufacturing Markets delivers innovative steel products to the building and construction, manufacturing, automotive and packaging industries, and to export customers. This business segment produces COLORBOND® steel and ZINCALUME® steel - two of Australian industry's best-known brands. These are foundation products for a wide range of steel applications, and bring unique structural and aesthetic choices to the market.

2004/05 was a difficult year for this business segment, as it dealt with the impact of dramatic increases in steel feedstock prices, as well as industrial action. This led to the segment recording an EBIT loss of $116 million. The second half-year saw earnings improve significantly as selling-price increases were implemented to restore margins. Our decision to withdraw from the export tinplate market resulted in $25 million of additional depreciation and restructure costs. Sales revenue for the year was up to $3.19 billion, compared with $2.88 billion the previous year.

WESTERN PORT

Our Western Port facility converts steel slab from Port Kembla into hot and cold rolled coil and metallic coated and painted steel products, including ZINCALUME® and COLORBOND® steels. Western Port is an important part of southern Australia's manufacturing and building sectors.

Industrial action during the year delayed completion of planned maintenance on the hot strip mill, cold strip mill, and other plants, and deprived Western Port of around 130,000 tonnes of production, at a cost of $40 million. Regrettably, many of our customers also experienced considerable disruption to their operations.

However, a site-based Enterprise Bargaining Agreement (EBA) was certified in March 2005, covering a four-year period. Our people put enormous energy into business recovery during the year, restoring delivery performance levels and ensuring our customers are restocked. Work to expand metallic coating capacity will be completed around the end of the 2005 calendar year, and will increase this capacity by 30,000 tonnes per annum.

Replacement of pickle tanks was successfully completed in January 2005. This will increase capacity by 15,000 tonnes per annum, and improve energy costs and operational security.

ILLAWARRA COATED PRODUCTS

In the Illawarra region of NSW, adjacent to Port Kembla Steelworks, we operate a group of facilities that convert steel feedstock to branded BlueScope Steel products such as COLORBOND® and ZINCALUME® steels. Tinplate and blackplate for our Australian packaging industry customers are also produced at this site.

In 2004/05, our Springhill coated steel plant again achieved several production records. For the first time the plant exceeded one million tonnes in total despatches, up 69,000 tonnes on last year, to 1.005 million tonnes. This was the plant's third successive record year for total despatches, while it also achieved the milestone of producing its 20 millionth tonne of metallic coated steel.

Separate production records were set by Springhill's rolling, metal coating, and painting operations. The cold rolling operation produced 934,000 tonnes, up from 901,000 tonnes the previous year. The metal coating operation produced 761,000 tonnes, up from 742,000 in 2003/04. The painting operation produced 158,000 tonnes, up from 152,000 in 2003/04. This excellent performance reflects the plant's strong focus on quality and manufacturing excellence.

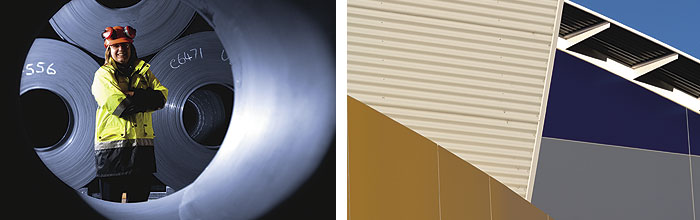

From left: Leanne Barrett, customer service manager, whose customers include Australian Manufacturing Markets;

From left: Leanne Barrett, customer service manager, whose customers include Australian Manufacturing Markets;A design feature from the Canberra International Sports and Aquatic Centre.

In 2004/05, brownfields initiatives continued to raise capacity and reduce costs. Modifications to paintline ovens, completed in March 2005, will deliver an additional 12,000 tonnes per year, while improvements to metal coating lines will deliver a full-year capacity increase of 35,000 tonnes.

WE DEALT WITH A NUMBER

OF CHALLENGES TO IMPROVE OUR EARNINGS

IN THE SECOND HALF.

After endeavouring for many years to make our packaging products business profitable in an oversupplied global market, we decided in April 2005 to withdraw from the export tinplate market. This will allow an additional 250,000 tonnes of hot rolled coil to be redirected to other, more profitable BlueScope Steel products and markets. During 2004/05, the packaging products business contributed an EBIT loss of $109 million to this business segment.

However, BlueScope Steel remains committed to the Australian packaging market. At the end of 2004/05, we negotiated new contracts with our major domestic customers.

These commitments reflect our strong value proposition, and will assist the ongoing viability of our domestic tinplate business. For the expected impact of the restructure of packaging products during 2005/06, please refer to Note 2 - 'Australian Equivalents to International Financial Reporting Standards.'

SERVICE CENTRE NETWORK

BlueScope Steel's Service Centre network processes flat steel products for use by the building and construction, automotive, whitegoods and rural sectors, and generates around 40 per cent of our Australian statebased sales of coated and painted products. The seven sites offer custom slitting and shearing services, while three - Acacia Ridge in Queensland, CRM at Port Kembla, and Chullora in NSW - also operate paint lines.

In 2004/05, the Service Centre network, like our other downstream businesses, was negatively affected by high input costs and industrial disputes.

During the year, scheduled outages on the Acacia Ridge and CRM paint lines caused a slight drop in production, down 4% on last year to 155,000 tonnes. However, increased demand saw slitting production up 1% on 2003/04, to 425,000 tonnes.

In December 2004, we announced the development of a new, state-of-the-art COLORBOND® facility in western Sydney at a capital cost of $120 million. The project, positioned to benefit from the rapid growth of the surrounding region, is expected to be operational by the middle of the 2006/07 financial year.